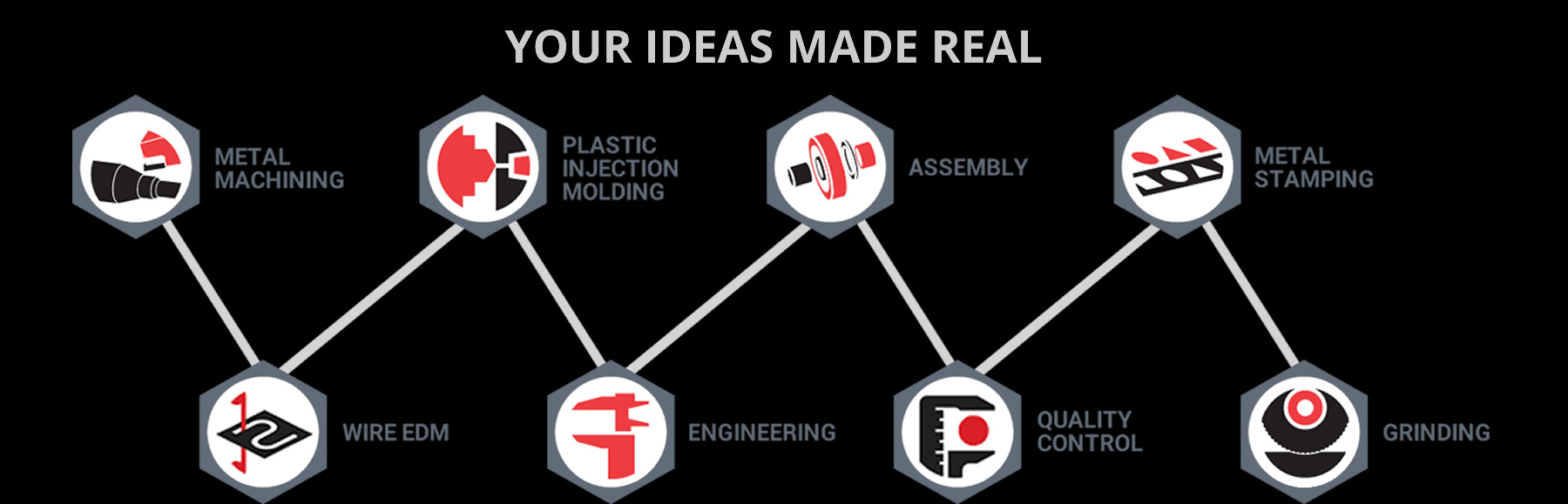

Contract Manufacturing – Making Your Ideas Real!

Specialty Integrated Services offers decades of expertise in contract manufacturing that includes: precision machining, metal stamping, injection molding, grinding, wire EDM and assembly that is all vertically integrated and under one roof. From value added engineering to assembly and packaging, our processes are refined for efficiency and repeatable high quality. Your ideas are made real in our 300,000 sq. ft. state of the art manufacturing floor. View our campus tour video to learn more.

PRECISION MACHINING

The Right Machines

- Low Volume to Large Production Runs

- Multi-Axis

- CNC Milling & Turning

- Swiss Turning

- Automatic Screw Machine

- Plastic Machining

METAL STAMPING

Any Volume

- 10 to 110 ton presses

- Compound and progressive

- Thicknesses from .003” up to .130″

- In house die building

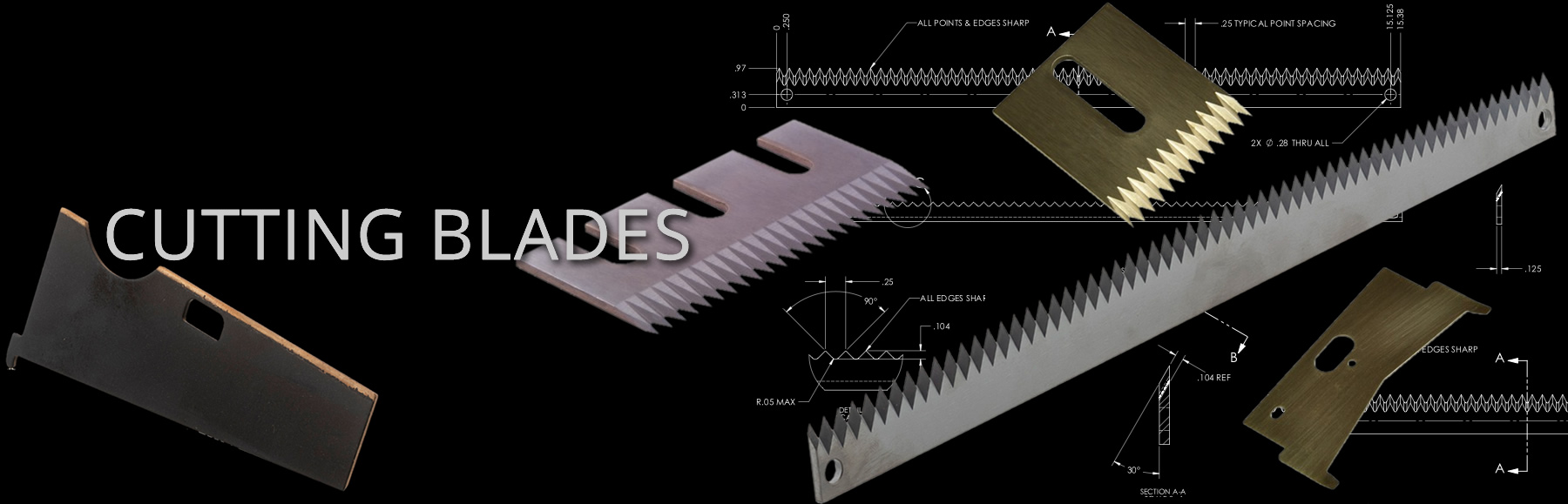

GRINDING

Proprietary Techniques

- Superior Edge Durability

- Crush Forming

- Press Metal Broach Cut

- Corrugated Blades

- In House Tooling

- Low to high volumes, competitively priced

PLASTIC INJECTION MOLDING

Shortest lead times in the business

- 80 to 500 Ton Presses

- Manual or automatic unscrewing molds

- Most engineering grades

- Short to long run

- Insert molding

- Design assistance

WIRE EDM

Extreme Precision

- Wire sizes 0.002″ to 0.012″

- Thicknesses 0.001″ to 10″

- Tight tolerances

- Minimal or no tooling charges

- Quick turnaround prototypes

Recent Posts

Industrial Machine Knives – Applications & Specialties

Industrial Machine Knives - Applications & Specialties Specialty Integrated Services [...]

Why Specialty Integrated?

Looking for contract manufacturing solutions in Minnesota and unsure where [...]

Specialty Integrated Services is one of five Specialty Manufacturing divisions. Since 1900, the company has applied it’s core manufacturing competencies to make customer ideas real. Our contract manufacturing customers around the world rely on our approach to problem solving and supply chain efficiency.

Specialty Integrated Services is known for precision machining, stamping, grinding and plastic injection molding. From cutting blades in any volume to 5 axis milling and plastic molding Specialty Mfg. has developed and perfected the skills to provide customers with the “tough parts” not readily available from other sources. Specialty Integrated Services is also known as a reliable partner experienced in assembly and quality operations along with in-house testing and production that is programmed to meet customer requirements.

We also offer value added design engineering expertise and CAD support along with many secondary operations such as cleaning, vibratory deburring, passivation, harperizing, assembly and packaging. All of this capability is housed in vertically integrated manufacturing production facilities in three campuses centrally located in Minnesota, USA.